What information needs to be determined for Siemens motor selection?

2023-03-23 22:02:28 1442

1、 Conditions related to model selection

There is a reasonable relationship between the selection of motor protection and the selection of protector. The following provides several conditions and factors related to protection to provide reference for users when selecting a type.

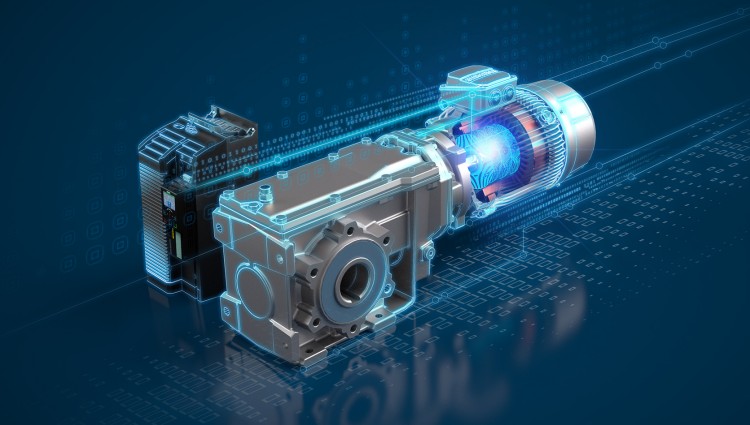

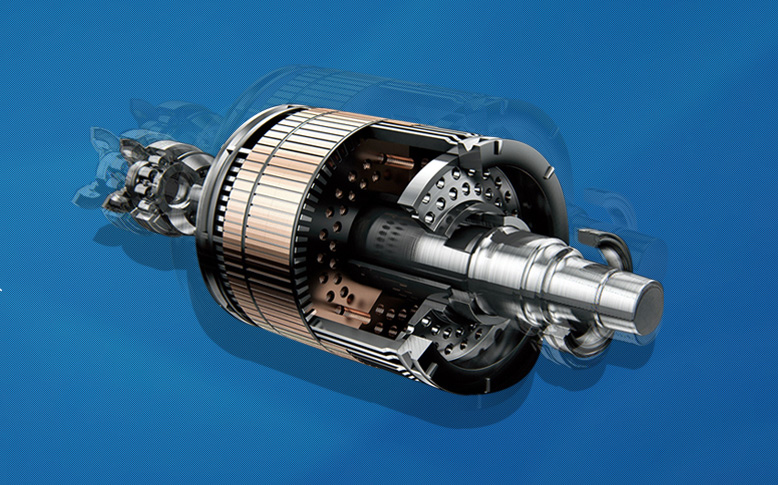

01. Motor

You should first understand the model and specification, motor functional characteristics, protection type, rated voltage, rated current, rated power, power frequency, insulation level, etc. These contents can basically provide a reference basis for users on how to correctly use and maintain and select protectors.

02. Environmental Conditions

It mainly refers to normal temperature, high temperature, high cold, corrosion, vibration, sandstorm, altitude, electromagnetic pollution, etc.

03. Motor Usage

It mainly refers to the required characteristics of drag mechanical equipment, such as different load mechanical characteristics such as fans, water pumps, air compressors, lathes, oil field pumping units, etc.

04. Control system

The control modes include manual, automatic, local control, remote control, stand-alone independent operation, and centralized control of the production line. Starting methods include direct, step-down, star delta, frequency sensitive rheostat, frequency converter, soft start, and other starting methods.

05. Other aspects

Whether users are casual or rigorous in managing on-site production monitoring, and the severity of the impact of abnormal downtime on production.

There are many other factors related to the selection of protectors, such as installation location, power supply, and coordination with the power distribution system; It is also necessary to consider whether to configure the protection of newly purchased motors, upgrade the protection of motors, or improve the protection of accident motors; The difficulty of changing the motor protection mode and the degree of impact on production should also be considered; The selection and adjustment of the protector should be comprehensively considered based on the actual working conditions on site.

2、 Selection of Siemens motors under operating conditions

1. For single machine independent running motors with low requirements for working conditions, simple operation control, casual monitoring and management, and little impact on production due to downtime, common type protectors can be selected. Due to their simple structure, on-site installation, wiring, replacement, and operation are simple and convenient, with high cost performance.

2. For MCC systems that require high working conditions, safety and continuity are critical, and have a high degree of automation, and require dedicated personnel to control, monitor, and manage them. For MCC systems that require network monitoring, mid to high-end, fully functional protectors should be selected.

3. For explosion-proof motors, eccentricity caused by bearing wear may lead to high temperatures at the explosion-proof clearance, creating an explosion hazard. Therefore, the wear status monitoring function should be selected. For large capacity high-pressure submersible pumps, due to the difficulty of inspection and maintenance, the wear status monitoring function should also be selected to avoid significant economic losses caused by bore cleaning accidents.

4. For protectors used in places with explosion-proof requirements, corresponding explosion-proof protectors should be selected according to the specific requirements of the application site to avoid safety accidents.

3、 Main functional characteristics of intelligent motor protector

Protection functions: overload protection, phase failure protection, three-phase imbalance protection, locked rotor protection, undervoltage protection, overvoltage protection, leakage protection, ground fault protection, light load protection, no-load protection, and short circuit protection.

Control functions: direct start, positive and negative start, star delta start, direct bypass start, autotransformer step-down start, and multi-party start control.

Display and monitoring: operation status, three-phase current, line voltage, leakage current, fault information, accumulated motor working time, fault frequency, and other information.

Setting functions: rated current, protection current curve, starting time, three-phase imbalance, locked rotor multiple, leakage current value, overvoltage/undervoltage value, communication address, protector power-on motor self starting time.

Remote transmission function: With DC4-20mA standard analog output, no external power supply is required.

Communication function: Through RS485 serial communication with a computer, a conventional protection and control network of 256 protectors can be formed. Remote data setting and display alarm, remote motor start, stop control, etc.

Recall function: It can store the causes of ten recent motor failures, and press the reset button to retrieve the fault code of the subsequent motor occurrence. Press again to display the previous one.

Previous:Siemens Motor - Motor authenticity check

Next:没有了!